US bridges are currently at a C+ rating, meaning that nearly 10% of all American bridges are structurally deficient, and nearly 40% are past their capacity to remain structurally efficient. To counteract these statistics, investments into repairing bridges must be made today. This calls for an innovative mindset for the sake of the US infrastructure getting a better-than-average grade.

Current Concrete Innovations

Self-Healing Concrete

This concrete fills cracks as they occur in bridges. The name itself explains its innovative qualities; a concrete that can heal its own wears and tears. This means that implementing this in new bridges will at least delay, if not completely negate the need for rehabilitation, an area the US is playing catch up in. With that being said, self-healing concrete does not solve the problem of cracks already in existence; it can only be a solution for new bridges.

A kind of bacteria is mixed into concrete during the construction of a new bridge. Over time, due to high traffic and weathering, concrete loosens and begins to crack. When a crack begins, water inevitably enters which activates the bacteria, causing it to grow. When this bacteria grows it produces limestone, a repair material filling the space.

Image Credit: Photograph taken by Andrew Stewart

Current Uses

This concrete has yet to hit the US market for several reasons. It costs around 3-4 times more than traditional concrete and there are concerns being raised regarding the sustainability of the product. When the bacteria is activated and begins to grow, will it influence air pollution in any way?

No matter where this innovation ends up being implemented, it’s bringing a new age of bio-thriving concrete to modern infrastructure.

Absorbent Concrete

This concrete absorbs water into it and through it to the ground it's covering, rather than having water run on top of it. With water being able to run through concrete, the water damage creating cracks in concrete is highly diminished.

It was invented with environmentally-friendly solutions in mind. Concrete covers a vast surface area that would normally be soaking up rainwater, benefiting the ecosystem. Because ”rainwater ends up falling on impervious surfaces such as parking lots, driveways, sidewalks, and streets rather than soaking into the soil … a host of problems including erosion, flash floods, water table depletion, and pollution of rivers occurs.”

Sustainable solutions is a rising and needed conversation within the US and this concrete takes that conversation very seriously.

Absorbent concrete is made of cement, coarse aggregate, and water, but it differs from impervious cement due to no sand being used in the mixture. This creates an ‘open-cell’ structure allowing water to flow through it, rather than run over it.

Image Credit: JJ Harrison

Current Uses

Absorbent concrete was first implemented in the Southeast region, specifically in Florida. This is because its warm enough that freeze-thaw damage isn’t a concern. When it was implemented in other climates, “significant concern [rose] among many groups, because of the high porosity of the concrete.” Along with freeze-thaw damage concerns, there are multiple other safety and durability questions being asked and tested. Because it's not the best solution due to a lack of durability and freeze-thaw problems in not-so-sunny climates, it's not the ideal solution for improving the US Infrastructure.

Proven Solution for US Bridge Infrastructure

So far, we’ve read about concrete that heals itself when cracks begin, but what if those cracks could be prevented from happening in the first place? This is possible with innovative concrete technology such as UHPC.

UHPC stands for Ultra-High Performance Concrete because it’s the antidote for traditional concrete in need of repair. Here are some of its qualities:

- High tensile & compressive strength

- High tensile & compressive strength- Impermeability to water

- Chemical and Chloride resistance

- Superior abrasion resistance

- Freeze/Thaw resistance

- Rapid setting times

UHPC was developed in the 1980’s for seismic structures that demanded super strength and corrosion resistance in Europe. Twenty years later in 2000, it became available in the states. “In a general sense, UHPC has proven to be particularly relevant in applications where conventional solutions are lacking” such as many of the bridges in the US. The materials of UHPC not only strengthen current structures but also extend their lifespan - something US infrastructure could definitely use. Those giving out the grades are hopeful as they see “New materials such as ultra-high performance concrete… are being used to add durability, higher strengths, resilience, and longer life to bridges.”

Created for bridge rehabilitation and deck-overlays, UHPC’s unique combination of materials “provides compressive strengths up to 29,000 pounds per square inch (psi) and flexural strengths up to 7,000 psi.” The high performance and strength of this concrete is created by a carefully selected combination of ingredients, including:

- Portland cement

- Silica Fume

- Quartz flour

- Fine silica sand

- High-range water reducer

- Water

- Steel or organic fibers

The chemical reactivity and extremely fine grain size, measuring at a maximum of 600 micrometers, are what provide the enhanced durability.

Current Uses

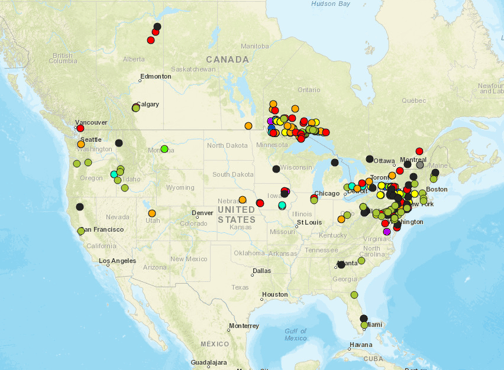

The first bridge constructed with UHPC in North America was the Mars Hill bridge in Wapello County, IA in 2008.

Here’s a map of current bridges and deck-overlays using UHPC in North America:

UHPC Solutions is providing innovative solutions for bridges and roads in need of repair. With a lighter weight, greater environmental resistance, and lower costs, UHPC Solutions can help to raise the grade on US bridges for years to come.

The concrete industry has to endure floods and water damage, support the varying weight of traffic, while also remaining sustainable. On top of that, it has to respond to customized requirements to fulfill ever-changing needs.

Self-healing concrete and pervious concrete have met some of these challenges. However, they’re still missing some key elements. UHPC Solutions, on the other hand, has developed the mindset overtime of preventing problems before they occur with their innovative solutions, solving concerns in today’s infrastructure landscape.