UHPC Defined

Ultra High Performance Concrete (UHPC) is a new class of concrete that has been developed in recent decades for its exceptional properties of strength and durability. This high performance concrete can be utilized in structural rehabilitation and accelerated bridge construction in addition to several other applications. Read on to learn more about the history of UHPC, its composition and applications.

Background

UHPC was first used by the U.S. Army Corps of Engineers in the late 1980’s and became available in the US in 2000. The commercial availability of UHPC allowed the Federal Highway Administration (FHWA) to start investigation in order to use UHPC for highway infrastructure. The FHWA investigations led to additional research from universities and demonstration projects. The result was a body of publications on UHPC and a long list of “bridge applications” including:

- Prestressed girders

- Precast waffle panels for bridge decks

- Field-cast closure pours for prefabricated bridge elements (Joint-Fills)

- Precast concrete piles

- Seismic retrofits of bridges

- Thin bonded overlays of bridge decks

- Security and blast mitigation applications

UHPC was first used in bridge construction in North America for a pedestrian bridge in Canada in 1997. Following that, 34 research projects were conducted throughout multiple research institutes for the goal of making UHPC a reliable, commonly available, economically feasible and regularly applied material. Germany also has several bridges using UHPC along with Australia, Austria, Croatia, Italy, Japan, Malaysia, the Netherlands, New Zealand, Slovenia, South Korea, and Switzerland.

Qualities

Why are all these countries taking advantage of UHPC? It’s an material that has a projected 100-year life span with exceptional strength, durability, flexibility and longevity.

Strength

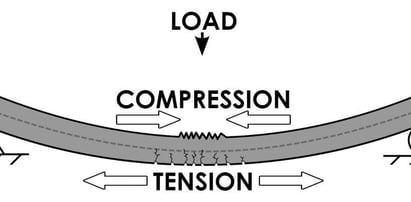

UHPC has a compressive strength 10 times that of traditional concrete. Compressive strength is the ability of a material to resist bending under a load (or in compression). Normal concrete used in bridges has a compressive strength of 3,000 to 5,000 psi. UHPC has a compressive strength of 18,000 to 35,000 psi. Another measure of strength is tensile strength or tension. This is how strong a material is when you pull it. While traditional concrete has a tensile strength of 400 – 700 psi, UHPC has a tensile strength of about 1400 psi.

Durability

While UHPC’s strength is impressive, it’s durability further exceeds expectations. Durability is measured by how the material performs under extreme conditions. Freeze/thaw resistance, chloride resistance (like in road salts) and abrasion resistance are all part of durability. UHPC has properties similar to hard rock.

Freeze/thaw resistance is tested by subjecting concrete prisms to freezing and thawing while submerged in a water bath. UHPC exhibited 100% of its material properties after 600 freeze/thaw cyles.

Chloride permeability is measured by ponding a 3-percent sodium chloride solution on the surface of the concrete for 90 days. After 90 days, the level of migration of chloride ions into the concrete is determined. UHPC showed extremely low chloride migration when tested, less than 10% the permeability of normal concrete.

Abrasion resistance is determined by measuring the amount of concrete abraded off a surface by a rotating cutter in a given time period. UHPC demonstrates excellent abrasion resistance, nearly twice as resistant as normal concrete.

- Salt-scaling (loss of residue): < 60 g/m2 (< 0.013 lb/ft3) Abrasion (relative volume loss index): 1.7

- Oxygen permeability: < 10-20 m2 (< 10-19 ft2) Cl - permeability (total load): < 10 C Carbonation depth: < 0.5 mm (< 0.02 in)

The durability of commercially available UHPC was independently evaluated through six standardized tests and the results are reported in the Journal of Civil Engineering. Those results show that UHPC has greatly enhanced durability over normal concrete used today regardless of the curing procedures:

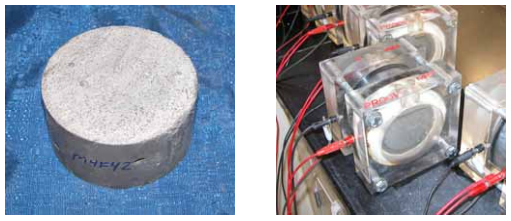

Cylinder and setup for rapid chloride ion penetrability test. Photo Credit: Journal of Civil Engineering

“The concrete exhibited minimal damage after being subjected to two times the normal number of ASTM C 666 freeze–thaw cycles. It was innocuous to ASTM C 1260 ASR deterioration, to ASTM C 672 scaling deterioration, and to AASHTO T259 chloride penetration. The ASTM C 1202 Electrical Indication of Concrete’s Ability to Resist Chloride Ion Penetration test result was negligible if any steam-based curing treatment was applied, and was very low otherwise.”

Materials

The materials within UHPC fall into three-component premixes: powders, superplasticizer, and organic fibers. The ingredients are:

- Portland cement

- Silica Fume

- Quartz flour

- Fine silica sand

- High-range water reducer

- Water

- Steel or organic fibers

What does this combination of components mean?:

Recently published articles, ‘Advances in Civil Engineering Materials’ and ‘Comparison of Conventional and Advanced Concrete Technologies in terms of Construction Efficiency’ both highlight that superior properties of UHPC reveal “distinguishable benefits” like:

- Simplified construction techniques

- Speed of construction

- Improved durability

- Reduced maintenance

- Reduced out-of-service

- Minimum interruption

- Reduced element size and complexity

- Extended usage life

- Improved resiliency

UHPC is material that is used world-wide due to its performance over normal concrete being “advanced, accelerated, and improved”. WALO and Posillico have teamed up to create UHPC Solutions. Our goal is to provide US bridge owners access to UHPC for bridge-deck overlays, rehabilitation projects or seismic structures. We specialize in accelerated bridge rehabilitation using UHPC to help solve the problem of deteriorating infrastructure in the US.